THERMAL SUPERVISION OF LARGE FURNACES

Multipoint temperature monitoring in industrial furnaces using Furthermon makes it possible to detect thermal deviations, cold spots, or overheating that affect both efficiency and process quality. Continuous measurement at up to 8 points with thermocouples provides a detailed view of the furnace’s thermal profile. With this data, it becomes possible to optimize heating cycles, reduce energy consumption, and anticipate operational problems before they turn into shutdowns or production rejects.

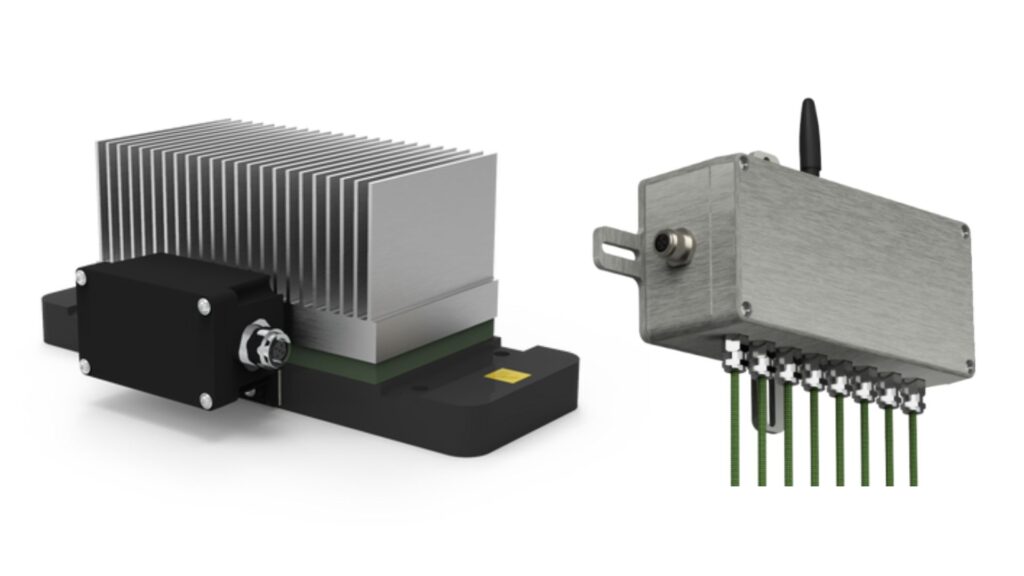

Furthermon

The first autonomous system on the market, fully self‑powered by the heat of the furnace itself, which enables continuous temperature monitoring at multiple critical points of the process using thermocouples.

Industrial furnaces are key equipment in sectors such as steel, aluminum, glass, ceramics, petrochemicals, or thermal and cement processing, where thermal stability is essential to ensure product quality and energy efficiency. Temperature deviations, cold spots, or overheating lead to increased fuel consumption, production rejects, refractory degradation, and unplanned shutdowns..

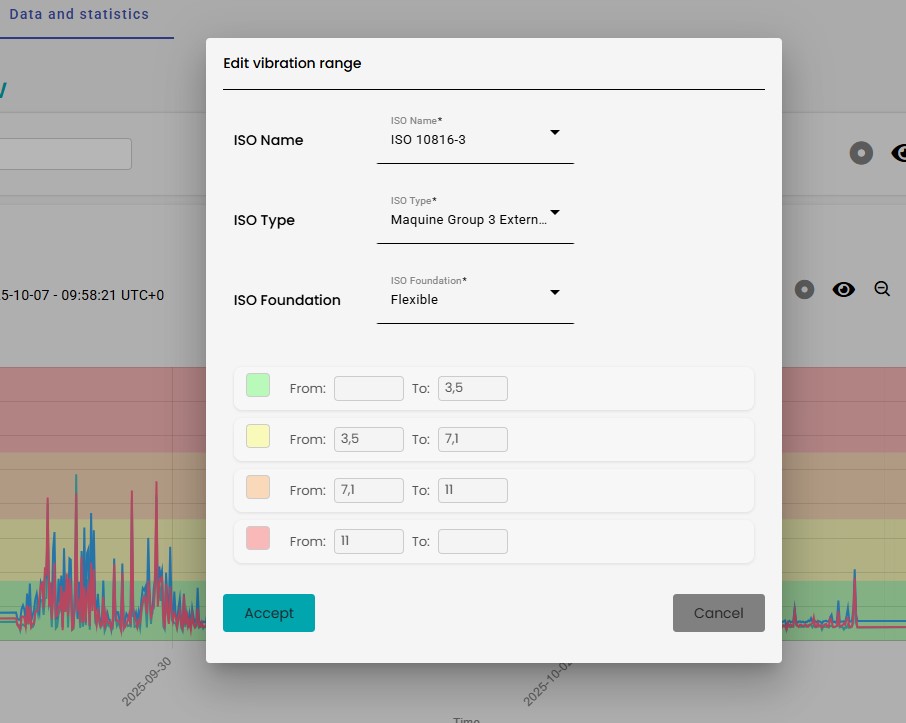

Furthermon enables continuous measurement of up to 8 temperature points using thermocouples in critical areas of the furnace, providing the real thermal profile of the process. Thanks to configurable alarms and trend analysis, it is possible to detect thermal imbalances, efficiency losses, and operational problems before they impact production.

Ideal for energy‑intensive industries such as steelmaking, aluminum, glass, ceramics, chemicals and oil & gas, and cement, where small thermal deviations can represent thousands of euros per day in energy overcosts and quality losses. Traditional solutions are not practical in these environments: batteries degraded by high temperatures, costly and fragile wiring, or short‑range wireless networks that require multiple repeaters and high infrastructure investments.

Forget about wiring and battery replacement: Furthermon is powered directly by process heat, sends continuous data (every minute), and offers ranges of up to 2 km per node, minimizing communication investment. It optimizes energy consumption, improves process stability, and reduces operational costs from day one. In addition, the solution allows access to energy incentive schemes such as CAEs in the EU.

Technology designed in collaboration with ArcelorMittal and ESBELT. Validated in steel plants and conveyor belts.

Main features

Thermoelectric generator

- Ambient temperature: -44°F to 122°F

- Surface temperature: 122°F to 316°F

Sensors

8 external temperature sensors (K-type thermocouples): from -20°C to 1100°C (accuracy 1°C)

Mounting surface

- Cylindrical adapter for steel pipes

- Others on request

Data update cycle

- 1 to 60 samples/hour

Integration

Designed to integrate with our Daevis cloud, third-party clouds, or other industrial platforms (SCADA, AVEA with OPC-UA or Modbus TCP/IP).