TRANSFORMAMOS EL CALOR Y LA ENERGÍA EN INFORMACIÓN Y CONTROL

NO PODEMOS VER EL FUTURO,

PERO LO PREDECIMOS.

CONOCE NUESTROS

PRODUCTOS AUTOINSTALABLES

PLUG & PLAY

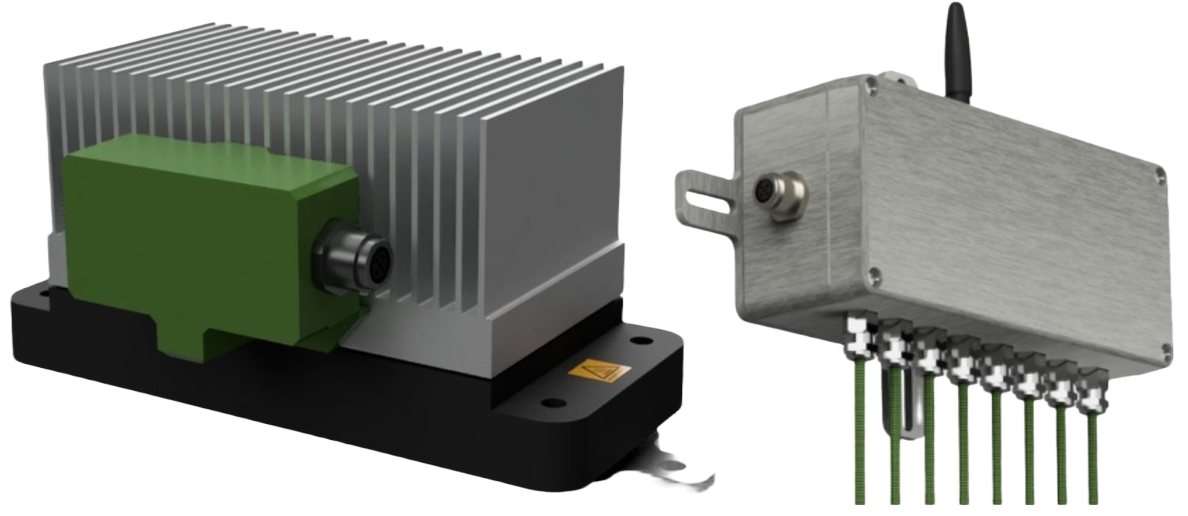

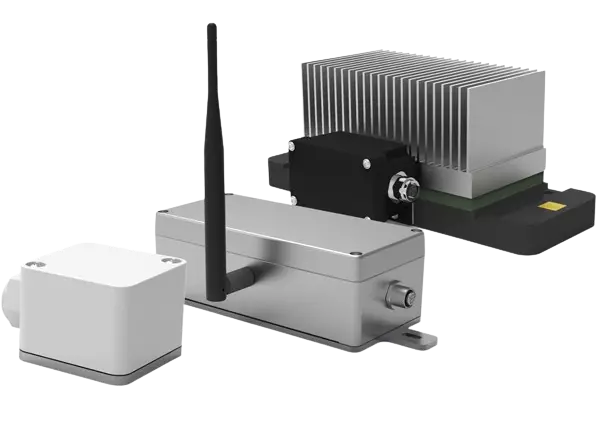

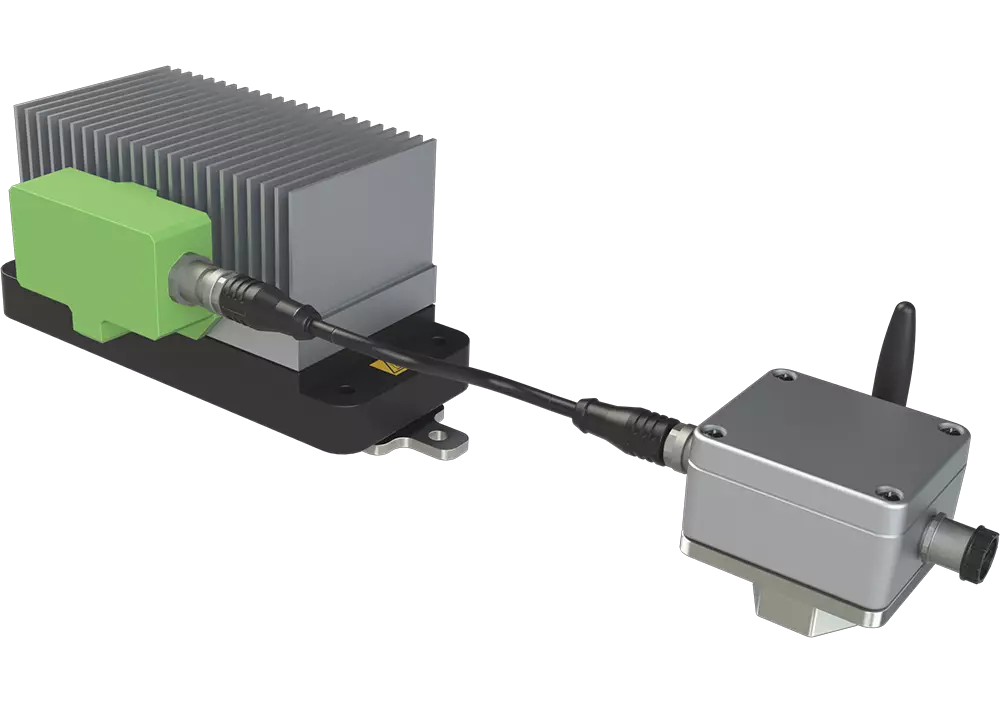

InduEye VibroSense 1

InduEye VibroSense 1 es el primer monitor inteligente de vibraciones tri–axial con certificado ATEX/IECEX alimentado por calor. Ideal para detectar anticipadamente fallos en máquinas rotativas. Optimiza el rendimiento de tus máquinas con precisión y seguridad.

- Bombas, motores, ventiladores, compresores y turbinas.

- Separadores centrífugos, sopladores, agitadores, expansores e intercambiadores de calor.

- Cajas de cambios, enfriadores, bandas transportadoras.

- Rodamientos.

- Estructuras.

- Martillos hidráulicos.

- Otras máquinas rotativas.

InduEye VibroSense 3

InduEye VibroSense 3 es la versión másplinko casino compacta con opción de medición precisa de temperatura y vibración. Con certificación ATEX/IECEX en trámite, es ideal para monitorear máquinas rotativas y procesos a altas temperaturas.most bet Mejora la supervisión de tus equipos con tecnología avanzada y precisión.

- Bombas, motores, ventiladores, compresores y turbinas.

- Separadores centrífugos, sopladores, agitadores, expansores e intercambiadores de calor.

- Cajas de cambios, enfriadores, bandas transportadoras.

- Rodamientos.

- Estructuras.

- Martillos hidráulicos.

- Otras máquinas rotativas.

- Temperaturas de hornos, chimeneas, y todo tipo de procesos a altas temperaturas.

InduEye TempSense

InduEye Extreme Temperatures Monitor

Furthermon es la primera solución de IoT industrial del mercado capaz de monitorizar de forma inalámbrica hasta ocho canales de temperatura mediante termopares en grandes hornos y procesos de alta temperatura, utilizando comunicaciones LoRaWAN de largo alcance. El equipo se alimenta completamente de calor residual, sin baterías y sin mantenimiento, lo que permite una operación verdaderamente autónoma en entornos industriales extremos.

Diseñado para aplicaciones en siderurgia y otras industrias pesadas, Furthermon permite un perfilado térmico multipunto continuo allí donde el cableado es complejo, costoso o inseguro. La solución facilita la detección temprana de desviaciones térmicas, calentamientos no homogéneos y degradación de refractarios, ayudando a optimizar la estabilidad del proceso, la calidad del producto y la eficiencia energética.

Al combinar sensórica de alta temperatura multicanal, energy harvesting y conectividad inalámbrica industrial, Furthermon posibilita el despliegue escalable de monitorización de hornos en grandes plantas con un esfuerzo mínimo de instalación. Ya validado en entornos industriales reales, aporta visibilidad Industria 4.0 a algunos de los procesos más intensivos en energía, apoyando estrategias de mantenimiento predictivo, optimización operativa y descarbonización.

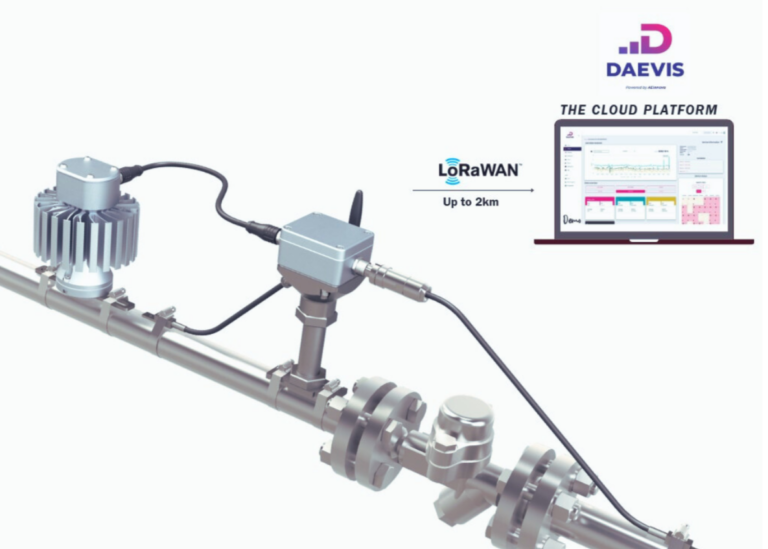

DAEVIS: Dynamic AEInnova VISualizer

DAEVIS (Dynamic AEInnova VISualizer) es la herramienta cloud propia para la gestión de datos de sensores para el mantenimiento predictivo. Utilizando las tecnologías más avanzadas, ofrece una supervisión robusta y segura de tus redes de sensores.

Controla dispositivos AEInnova InduEye y de terceros desde una interfaz única. ¡Supervisa todo, en cualquier lugar y en cualquier momento!

Instalación no invasiva: no necesitará parar la producción para su instalación. Para instalaciones críticas, DAEVIS puede desplegarse in situ (en sus propios servidores de IT) para garantizar la confidencialidad y solidez.

TU PRODUCCIÓN

NON-STOP

InduEye es un sistema de monitoreo que utiliza energía del calor residual.

Fácil de instalar y confiable, permite monitorear su maquinaria, prediciendo el mejor momento para el mantenimiento.

SIN RIESGOS

Sistema industrial robusto, confiable y fácil de instalar.

SIN PÉRDIDAS

Aumentamos la productividad de la maquinaria de producción.

SIN CORTES

Instalación no invasiva: no necesitará parar o romper la cadena de producción de la empresa.

TECNOLOGÍA ESPACIAL

PARA EL CONTROL EFECTIVO

DE TU MAQUINARIA

CON NOSOTROS

TU TRANQUILIDAD

ESTÁ GARANTIZADA

MEDICIÓN Y PREDICCIÓN DE LARGO ALCANCE

SIN BATERÍA

SIN MANTENIMIENTO

LA INDUSTRIA 4.0 YA ESTÁ AQUÍ

Fabricado en Barcelona para transformar el mundo haciéndolo más sostenible.

El mantenimiento predictivo y proactivo de tu industria como nunca antes lo hubieras imaginado. Damos la bienvenida al primer IIOT NETZERO del mercado alimentado con tecnología espacial.

Los primeros dispositivos de medición autónomos con comunicación de largo alcance, sin baterías, sin mantenimiento, autoalimentados por calor residual para la supervisión de tus procesos productivos.

MAXIMIZA LA PRODUCCIÓN REDUCIENDO LOS COSTES DE MANTENIMIENTO

MINIMIZA LA INVERSIÓN EN TU TRANSFORMACIÓN DIGITAL

EVITA LAS PÉRDIDAS POR PARADA INESPERADA

DIAGNOSTICA LAS POSIBLES AVERÍAS ANTES DE QUE OCURRAN

CONTRIBUYE A LA DESCARBONIZACIÓN DE TUS INSTALACIONES

MEJORA TUS PROCESOS

CON LA TECNOLÓGÍA MÁS AVANZADA

CONFÍA EN LA PRECISIÓN

CASOS DE ÉXITO

Hemos ayudado a monitorizar procesos en industrias pesadas en todos los ámbitos industriales (oil&gas, siderurgia, cemento, papel, plástico, plantas de lixiviación, químico, EDAR, etc) en 5 países.

PREMIOS

Somos una de las compañías más premiadas a nivel internacional con más de 30 reconocimientos, varios de ellos de Naciones Unidas. Nuestra fusión de tecnologías deeptech con la sostenibilidad, es el ingredientes clave para contribuir a una industria más eficiente con menor impacto ambiental.

PROYECTOS I+D

AEInnova está participando en 8 proyectos Europeos en consorcio con decenas de entidades de investigación Europeas para el desarrollo de la tecnología que ahora es una realidad.

INNOVACIÓN EN LA SUPERVISIÓN

DE PROCESOS PRODUCTIVOS