STEAM LEAK DETECTION

IN STEAM TRAPS

Steam System

Efficiency Assessment

Measuring losses in steam traps allows steam leaks to be identified and equipment that is not functioning correctly to be detected. This analysis quantifies the energy and economic impact associated with losses, providing an accurate picture of the state of the system. Thanks to this information, improvements can be implemented to optimize the overall performance of the installation and reduce operating costs.

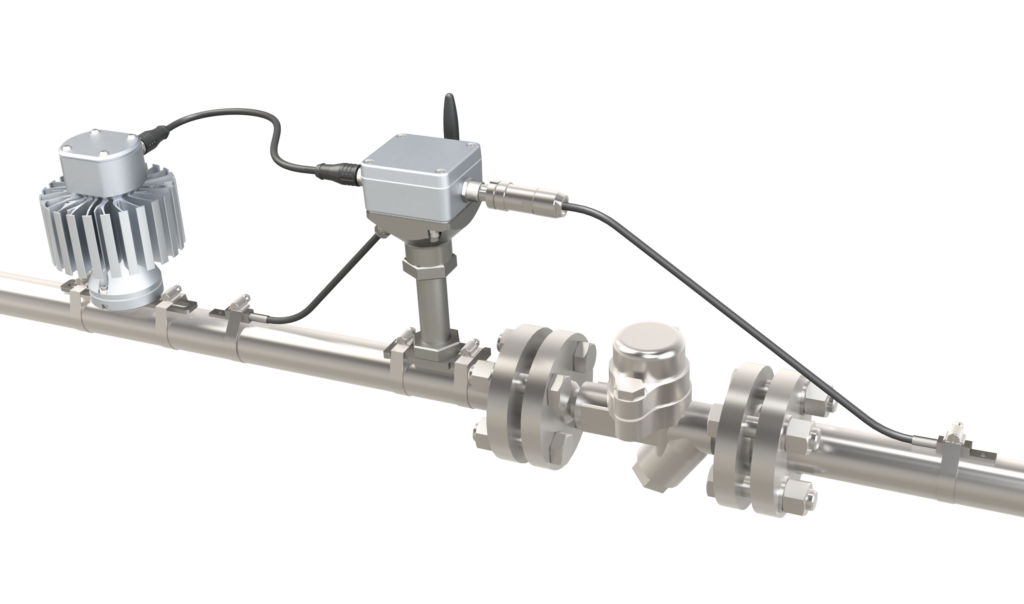

TempSense

The first autonomous device on the market, completely self-powered by process heat, ATEX certified, enabling continuous monitoring of the status of your steam traps and valves. .

Steam traps are devices that allow condensed water to be evacuated from steam lines to prevent water hammer and other problems in your lines. Due to their operating principle, these devices have high failure rates (15-30%). These failures can cause the trap to remain permanently open for months, resulting in tens of thousands of euros in steam losses. They can also remain closed, causing safety issues and other associated costs.

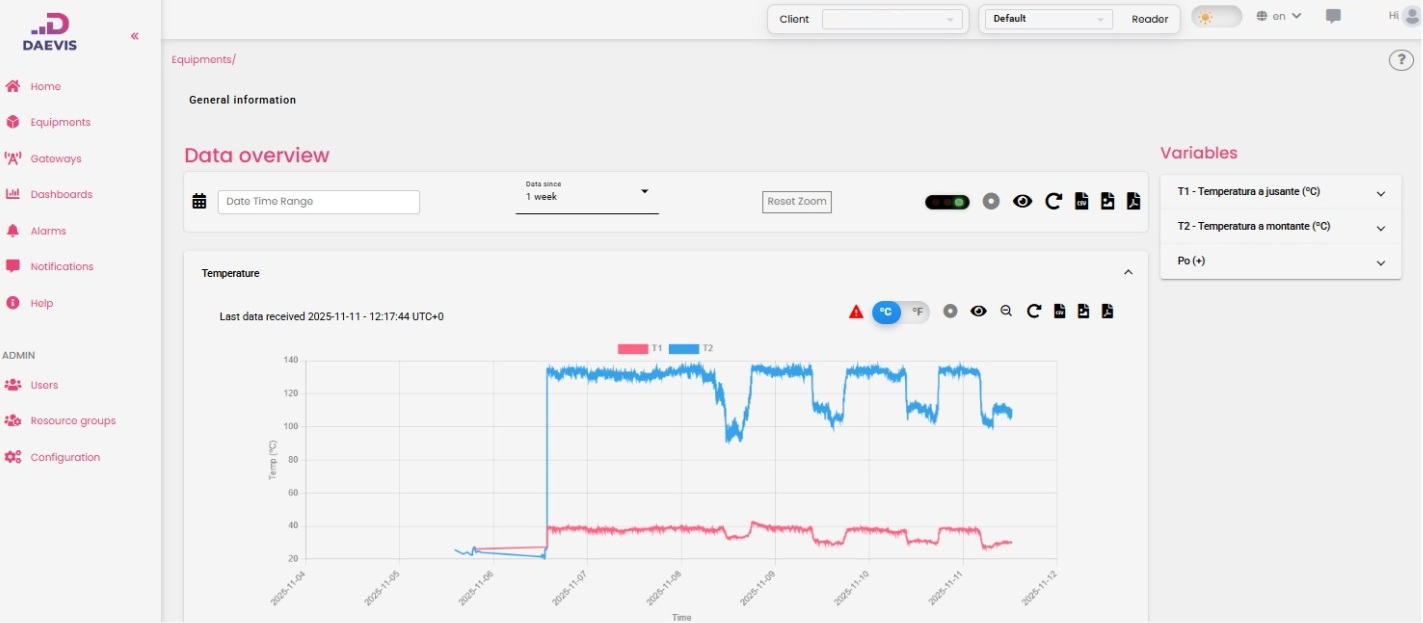

Our TempeSense product allows you to monitor the temperatures of thermostatic, thermodynamic, and float steam traps for precise, continuous control of “inlet” and “outlet” temperatures and to identify their correct operation with preset alarms.

Ideal for pharmaceutical, chemical, petrochemical, and oil & gas industries, where millions of euros are lost annually due to lack of supervision. Competitors’ equipment is impractical (constant replacement of batteries affected by process heat, inefficient solar panel-powered systems, dependence on complex wired installations or wireless systems with very short range requiring substantial investment in repeaters).

Forget about battery replacement and maintenance forever, obtain continuous data (every minute), minimize investment in wireless infrastructure (range of up to 2 km per node), and reduce your energy costs to a minimum. In addition, this solution will allow you to benefit from CAES in the EU.

Technology designed in collaboration with the REPSOL Foundation Entrepreneurs Fund. Validated in large petrochemical and oil plants internationally.

Thermoelectric generator

- Ambient temperature: from -20ºC a 60ºC

-Surface temperature:

from80ºC a 180ºC

Sensors

- Dual external temperature sensor (PT100): from -20°C to 400°C (accuracy 0.1°C)

Mounting surfaces

- Cylindrical adapter for steel pipes

- Others on request

Data update cycle

- 1 to 60 samples/hour

Integration

Designed to integrate with our Daevis cloud, third-party clouds, or other industrial platforms (SCADA, AVEA with OPC-UA or Modbus TCP/IP).