VIBRATION MEASUREMENT

Unexpected production stoppages represent at least 5% of the industry’s production capacity, but 80% of industries are not able to accurately estimate their stoppages.

Continuous monitoring of your machines will allow you to extend the useful life of your assets, reducing maintenance costs, breakdowns, downtime and increasing productivity and profits.

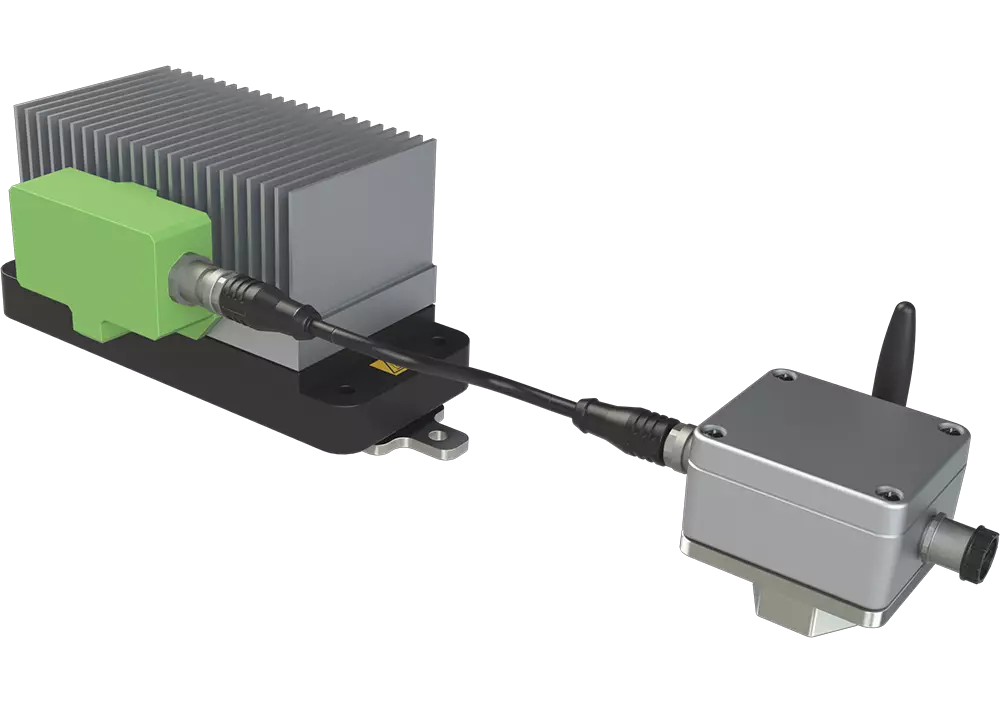

At Aeinnova we present the first commercial Wireless long-range device on the market, completely autonomous, powered by the heat of the industrial process, without batteries and without maintenance for remote monitoring of your machines, through the control of their vibrations and temperature. Alternatively, this Wireless device can also be powered by wind or mains.

InduEye Vibro 1.0

The first stand-alone intelligent monitoring product with which you can diagnose rotating equipment, verify the operation of bearings and gears, and test electric motors on the following machines:

- Pumps, motors, fans, compressors and turbines.

- Centrifugal separators, blowers, agitators, expanders and heat exchangers.

- Gearboxes, coolers, conveyor belts.

- Roller bearings.

- Water hammer.

It is designed to work in extreme environments, which makes it suitable for multiple industrial sectors such as steel, cement, leachate plants, water purification plants, etc.

CERTIFICATION:

– ATEX/ IECEX available for industries with explosive atmospheres (oil and gas, chemical, etc.).

– CE/MIC (Japan)

InduEye Vibro 3.0

Following the success of version 1.0, this new version simplifies the hardware and integrates the triaxial sensor and the LoRaWAN communications node in the same device.

At the same time, this new version allows the connection of a high precision and high range temperature sensor, and allows the connection of up to two more nodes using the same thermoelectric generator.

Its spectral analysis capability (0 Hz up to 4 kHz/6 kHz) allows for easy diagnosis of functional anomalies in the equipment, by visualizing the complete or segmented spectrum, enabling the detection of imbalances, misalignments, bearing problems, lack of lubrication, cavitation, etc.

This set-up allows to reduce costs and make the solution more flexible by adding more sensors and more measurement axes.

Additionally, with its expansion port, it is possible to power up to three InduEye Vibro nodes with a single thermoelectric generator.

OPTIONAL:

– External temperature sensor (PT100).

– Power supply: 220VAC–110VAC or 24VDC

– Measurement of kurtosis, crest factor, peak-to-peak, phase… (Q1-2026)

For more information, please contact us!

Thermoelectric generator

- Ambient temperature:

from -20 ºC to 50 ºC

- Surface temperature:

from 50 ºC to 150 ºC

Upgradeable

- Temperature sensor (PT100):

from -20 ºC to 400 ºC

- Up to 3 InduEye with the same thermoelectric generator

Mounting surfaces

Flat or tube

Data update cycle

-1 to 10 samples/hour ATEX

-1 to 6 samples/hour NO ATEX

Measurement

- Velocity (RMS): 0-180 mm/s

- Acceleration (g): 0-157 mm/s

- FFT: Full spectrum from 1–4/6 kHz, or by ranges for early fault detection.

Long-range communications sensor

- LoRaWan (up to 2 km)

- NB-IOT (up to 23 km)

- Installation in less than 5 minutes

- Place the thermoelectric generator next to a heat source (at least 25ºC withrespect to ambient temperature or 50ºC if it is ATEX).

- Place the triaxial vibration sensor in the critical area to be monitored.

- Finally place the LoraWAN IoT device in an unobtrusive location out of the heat, and up to 2m away from the generator (10m with extender).

And that’s it! You will have your machine’s data in the Cloud in the blink of an eye.

Boiler | Centrifugal fan | Centrifugal pump | Compressor | Condenser | Furnace | Gas engine | Gear box | Generator | Industrial fan | Motor | Turbine | Water treatment