STEAM TRAPS

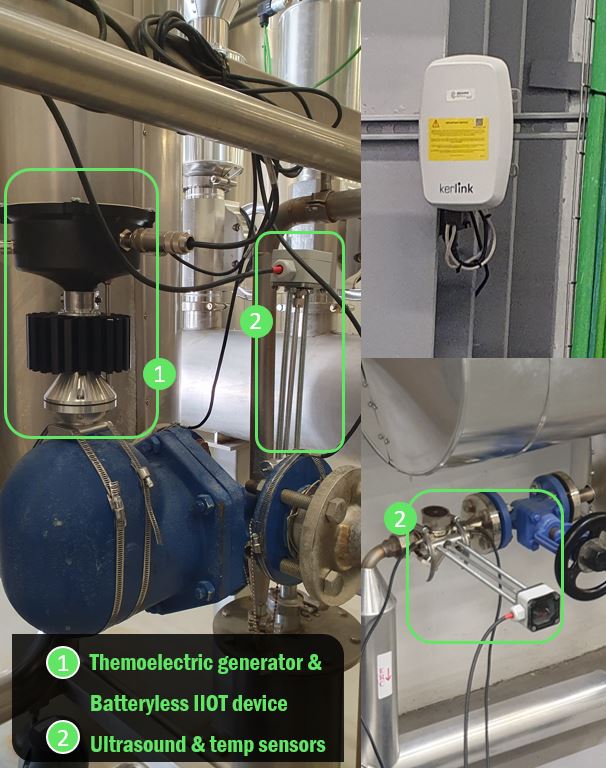

Waste heat revalorization for the total lithium battery suppresion in steam pipeline sensing

Overall numbers in an oil refinery

20,000 Steam Traps

These are the typical steam traps located in a medium-sized oil refinery

Steam Leaks

A conventional locked steam trap lose from 4 kg/h up to 15 kg/h of steam.

1,200 USD / Year

Working 8,000 hour / year, with 15 kg/h of Steam at 10 USD / 1000kg.

Development stage

1st Stage- 2021

1st pilot developed for measuring steam leaks in a steam pipe of soybean plant. Equipment fully powered by waste heat.

2nd Stage- 2022

LoRaWAN IoT device with 2km of wireless range, developed under ATEX constraints, measuring Delta T in the steam trap every 2 minutes.

3nd Stage- 2023

Ultrasound fine tunning to detect steam whislisting in combination with Delta T, to supress false-positives commonly found in previous versions.

Commercial Version (Q3-2024)

- Uses waste heat from the steam pipeline for powering the steam leaks detection devices:

- Temperature 120º

- Fast and low-cost deployment: estimated ROY of 10 months

- High precision and accuracy

- Inlet/outlet temperature and high spectrum ultrasounds

- Savings up to 1,200 USD / year / unit:

- Steam leaks

- Audits

- Battery replacements

Project partners

Project cofinanced by the Catalan Government- ACCIÓ- Nuclis d’economia Circulat.