USE CASES FOR THE PAPER, TEXTILE, FOOD AND WATER INDUSTRY

GENERAL BENEFITS

- Less CAPEX than wired network

- Less OPEX than most of the products on the market

- Reduction in maintenance costs

- Elmination of unexpected breakdowns

- Reduction of costs and risks of downtimes

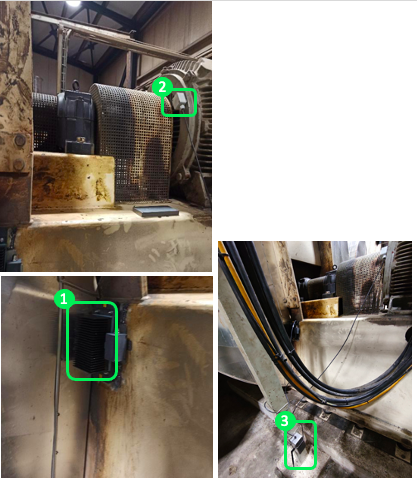

PAPER INDUSTRY

Vibration on a dryer in a paper plant production

| 1. Thermoelectric generator |

|

| 2. The vibration sensor |

|

| 3. Wireless iIoT device |

|

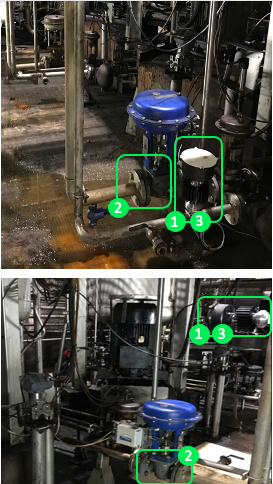

TEXTILE INDUSTRY

Steam leaks detection in steam traps and vibrations on a autoclave in a textile production plant

| 1. Thermoelectric generator |

|

| 2. The ultrasound and vibration sensor |

|

| 3. Wireless iIoT device |

|

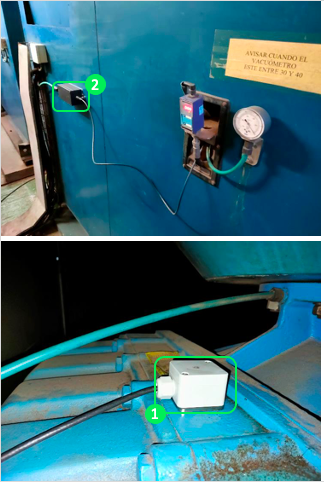

FOOD INDUSTRY

Steam leaks detection in a soybean processing plant

| 1. Thermoelectric generator |

|

| 2. The ultrasound / temperature sensor |

|

| 3. Wireless iIoT device |

|

WATER INDUSTRY

Vibration on a sludge dryer in a wastewater treatment plant

| 1. The vibration sensor |

|

| 2. Wireless iIoT device |

|