InduEyeTM TERMO LoRa VIBRO

The complete solution to

Vibration Condition Monitoring

Downtime costs every factory at least 5% of its productive capacity, and many lose up to 20%. But an estimated 80% of industrial facilities are unable to accurately estimate their total downtime cost (TDC). Many of these facilities are underestimating their downtime by 200-300% according to downtime consultants.

Article written by Dave Crumrine and Doug Post, of Interstates.

InduEye Termo LoRa Vibro 1.0 is a Smart Monitoring product with which you can diagnose rotating equipment, check the operation of bearing – gears and test electric motors in the following machines:

- Pumps, motors, fans, compressors, and turbines.

- Centrifugal separators, blowers, agitators, expenders, and heat exchangers.

- Gearboxes, chillers, belt conveyors.

- Rolling bearings.

- Fluid hammer.

It is designed to work in extreme environments and is ATEX compliant, which makes it suitable for multiple industrial sectors such as oil and gas, chemicals and cement.

A flexible and scalable solution that will allow you to make a smooth transition to Industry 4.0.

If you would like to have the right part in the right place, at the right time, contact us!

InduEye Termo LoRa Vibro 1.3 is a Smart Monitoring product with the same benefits as version 1.0 but with a significant size reduction.

- VIBRO SENSOR + TEMPERATURE SENSOR + IOT NODE + More devices, all-in-one.

HOT NEWS! Product will be available by the end of Q1-2024 !

It is designed to work in extreme environments and is ATEX compliant (Q3-2024), which makes it suitable for multiple industrial sectors such as oil and gas, chemicals and cement.

A flexible and scalable solution that will allow you to make a smooth transition to Industry 4.0.

If you would like to have the right part in the right place, at the right time, contact us!

InduEye® LoRa Vibro v1.3 is coming…

Key Features

In addition to all the general features of InduEye, the InduEye VIBRO solution offers the following key features:

Working temperatures

Thermoelectric from 50 ºC to 150 ºC (25ºC - 50ºC ATEX ΔT)

Ambient temperature

-20 ºC to 60 ºC

Long-range communications

LoRaWAN / NB-IOT

RMS Velocity

Range of velocity: 0-180mm/s

Accuracy of measure: 0,01 mm/s

Spectrum range

From 10Hz to 2 KHz

Mounting surfaces

Plain or pipe

Savings

Environmental impact

96% reduction in carbon emissions, water usage, heat and energy consumption.

500Kg CO2 eq/ device yearly

Elimitation of breakdowns

Up to 75% breakdowns reduction.

Reduction in downtime

The unplanned downtime of the machine will decrease up to 45%.

Increase in productivity

Increase the productivity up to 25%.

Reduce risks

Risks on safety, health, environment and quality will decrease by 14%.

Reduction in maintenance costs

More than 200€ / yearly in battery replacements + personal costs + process stop.

Infrastructures

LoRaWAN > 80% compared with any wireless solutions.

System Description

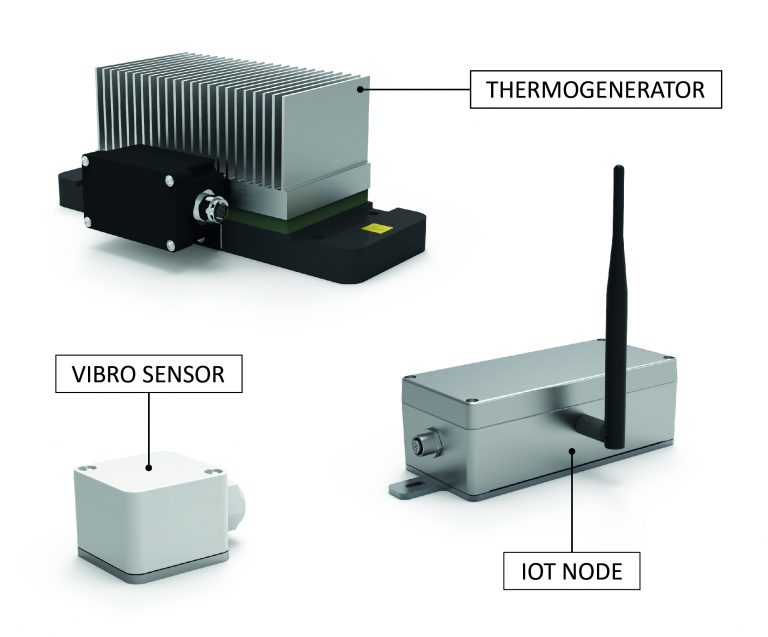

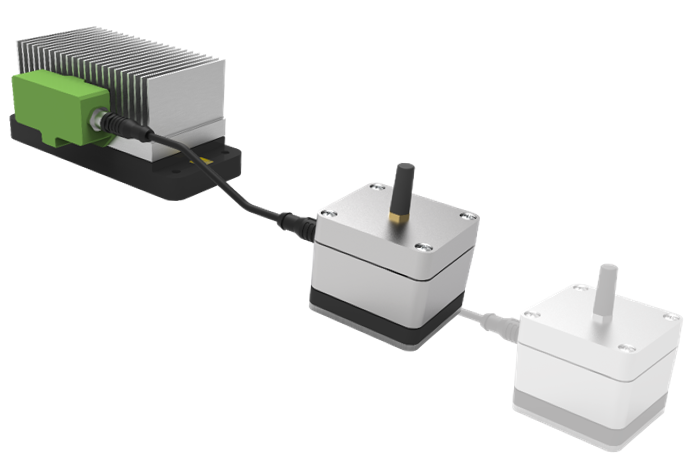

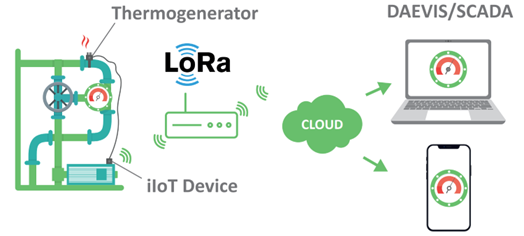

InduEye Termo LoRa Vibro 1.0 is a complete IoT platform designed for the industry and composed of the following 3 components and a cloud dashboard:

- Thermogenerator: our awarded and patented thermoelectric generator.

- Sensor: a high performance industrial vibration sensor.

- Node: a wireless IoT device for communication or a wireless IoT device plus a 3rd Party LoRaWAN gateway for LoRaWAN communications.

- Daevis: it is our data processing and monitoring center, where all data is presented in a highly customizable dashboard.

Always on, always monitored

The industry requires large display formats and more flexible control data. Currently, the SCADA platforms are highly expensive, inflexible, and too little handling capacity.

DAEVIS (stands for Dynamic AEInnova Visualizer) is our proprietary cloud-based web monitoring dashboard. It is flexible, customizable, and deployed in the cloud or on-premises (installed on client-server). Complete control of any process, anywhere, and control the power of historical and real-time alerts, telegram notifications, and predictive maintenance tools.

Applications

Water treatment

Short demo at ADIPEC Oil&Gas fair - Abu Dhabi

Contact us

InduEye Termo LoRa Vibro 1.0 is a Smart Monitoring product with which you can diagnose rotating equipment, check the operation of bearing – gears and test electric motors in the following machines:

- Pumps, motors, fans, compressors, and turbines.

- Centrifugal separators, blowers, agitators, expenders, and heat exchangers.

- Gearboxes, chillers, belt conveyors.

- Rolling bearings.

- Fluid hammer.

It is designed to work in extreme environments and is ATEX compliant, which makes it suitable for multiple industrial sectors such as oil and gas, chemicals and cement.

A flexible and scalable solution that will allow you to make a smooth transition to Industry 4.0.

If you would like to have the right part in the right place, at the right time, contact us!