"Revalorització del calor residual per a l'eliminació de bateries de liti en sensorització de línies de vapor"

Waste heat revalorization for the total Lithium battery suppresion in steam pipeline sensing

Overall numbers in an Oil Refinery

20,000 Steam Traps

These are the typical steam traps located in a medium-sized Oil Refinery.

Steam Leaks

A conventional locked steam trap lose from 4 kg/h up to 15 kg/h of steam.

1,200 USD / Year

Working 8,000 hour / year, with 15 kg/h of Steam at 10 USD / 1000kg.

Development stage

1st Stage - 2021

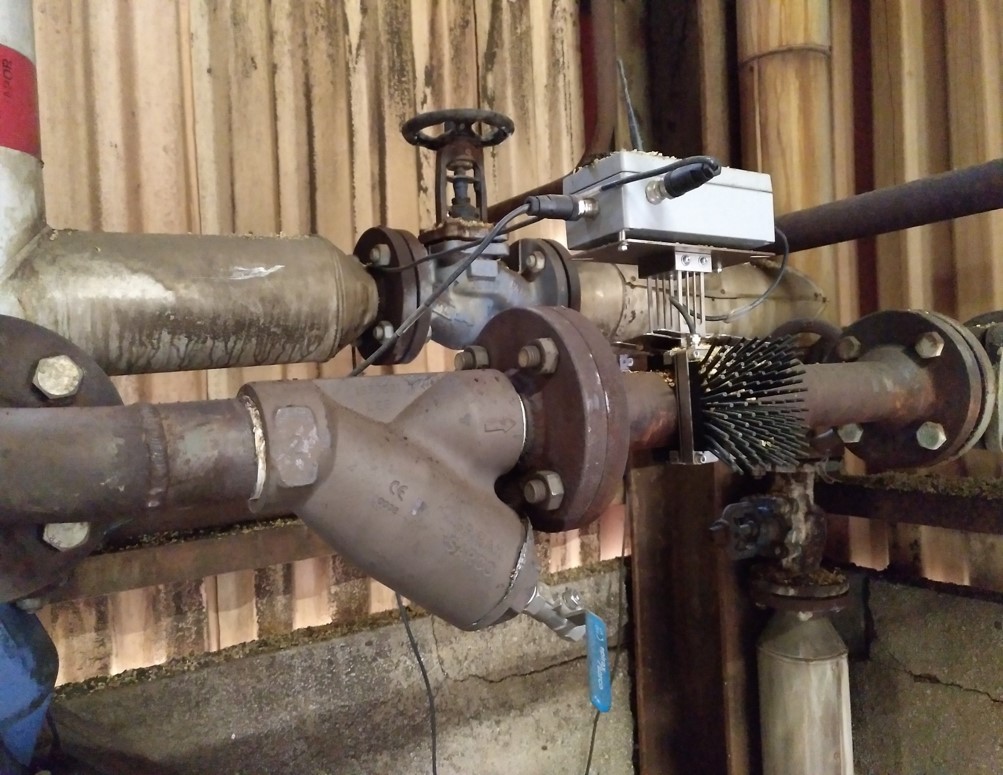

1st Pilot developed for measuring steam leaks in a steam pipe of a soybean plant. Equipment fully powered by waste heat.

Goal achieved!

LoRaWAN IoT device with 2Km of wireless range, developed under ATEX constraints, measuring Delta T in the steam trap every 2 minutes.

2nd Stage -

2022

Ultrasound fine tunning to detect steam whistling in combination with Delta T, to supress false-positives commonly found in previous versions. Ready in Q2-2022 with CE Mark and ATEX certification.

First Pilot installed in BUNGE

Project partners

Project cofinanced by the Catalan Goverment – ACCIó – Nuclis d’economia Circular.