Battery – Less Sensor Project

The Battery – Less Sensor project consists of using the waste heat present in the processes to power a new generation of wireless sensors without the need for batteries. It allows measuring temperature and vibration in industrial processes or monitoring rotating machines to facilitate predictive maintenance, avoiding production stoppages, and creating early warnings of potential failures in industrial processes.

It is financed by AEI lines of the Ministry of Industry, Trade, and Tourism. It is an IoT initiative developed by AEInnova together with Valoriza Servicios Medioambientales and the Cluster de l’Energia Efficient de Catalunya.

The characteristics of the project were explained in the table:

| Company |  |

| Location | Valoriza Servicios Medioambientales: Chiloeches (Guadalajara – Spain) and CIRTEC: Valdemoro (Madrid – Spain) |

| Implementation time | 3 months |

| Need | Monitoring of operating parameters (vibrations and temperature) in the rasper from VSM and two reactors from CIRTEC. |

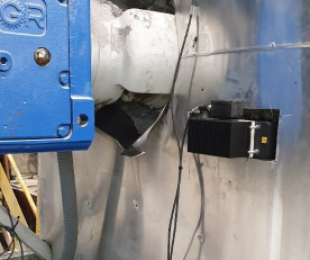

| Solution | The solution consists of installing three INDU-EYE LoRa Vibro and three INDU-EYE LoRa Termo (on the bearing support of the granulator motor, and on the jet engine cover) The installation consists of 4 components:

|